|

|

|

SY-CON EM

Maintenance Management

Maintenance =

Parts, labor, and

procedures to make or keep equipment operative.

SY-CON EM provides maintenance personnel with

powerful feature-packed software to make managing

maintenance activities uncomplicated with work orders for:

►Preventative Maintenance

►Equipment Repairs ►to Service Companies

►Facility Repairs

Designed for Paperless Operation

How

SY-CON EM and PC-TOOLCRIB Work Together

(See

PC-TOOLCRIB Lite

to find out how it works with it.)

In

PC-TOOLCRIB

● The

inventory management strengths of PC-TOOLCRIB are used to handle MRO items,

tools, serialized

assets, shelf-life

products, and repair kits needed for work orders, and

it makes sure they are in stock or

orders them when needed.

● Items needed for a

WO can be issued from PC-TOOLCRIB or from SY-CON EM and are charged to

the WO by scanning/entering the WO

barcode. The item costs are immediately included in the

work order costs along with any

labor costs within SY-CON EM.

● Inventory quantities are decremented on

WO issue whether done from PC-TOOLCRIB or

SY-CON EM.

● Build kits

containing all MRO, special tools or serialized assets like test equipment, and

chemicals

needed as spare parts for each

specific equipment number, an entire category of equipment

(e.g.

all

gas-driven compressors) or what's needed for

a specific repair task.

In SY-CON EM

● Spare

parts list can include MRO items, shelf life products, and tools from PC-TOOLCRIB

●

Real-time

drill-down search

for MRO and tools.

● Quickly add

any kit built in PC-TOOLCRIB as a spare parts list or task parts list.

● Check

spare parts and kits live inventory level and if low place on order

● Use serial

numbered parts (e.g. motors) to keep track of what

is now in-service in the equipment.

SY-CON EM

Features

|

|

|

| |

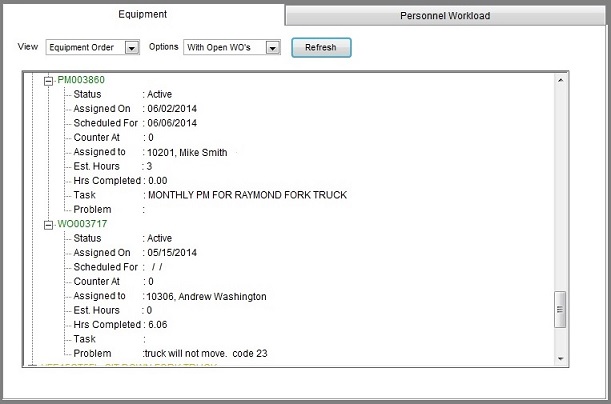

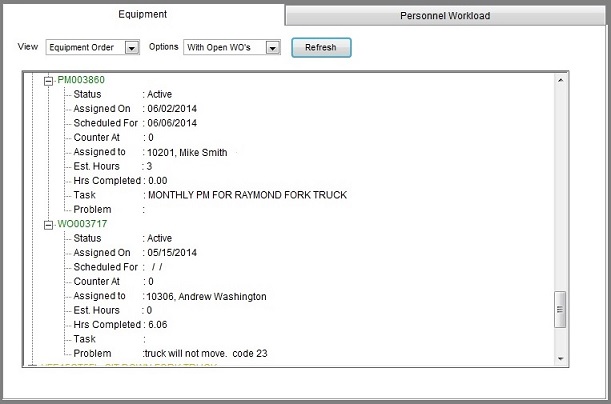

Status Overview Dashboard

|

|